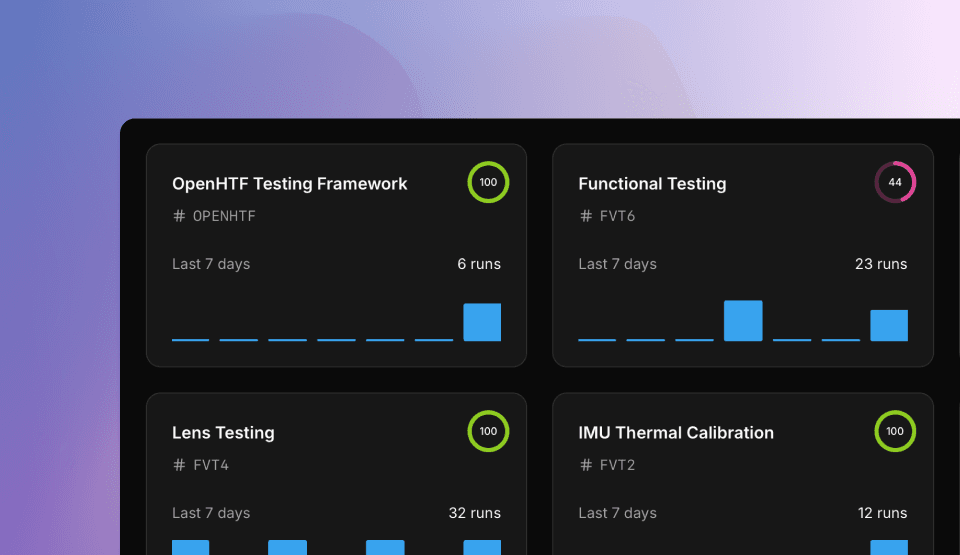

Procedures

Define test scripts and analyze performance metrics.

Overview

A Procedure represents your test script and links it to analytics, yield tracking, and production stations. It aggregates results from multiple runs to provide insights into test performance and quality trends.

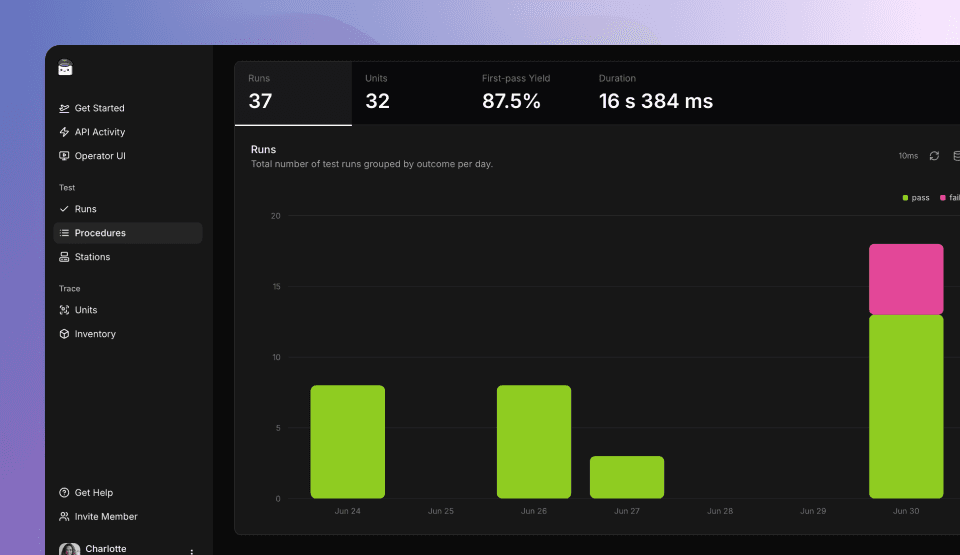

Analyze Runs

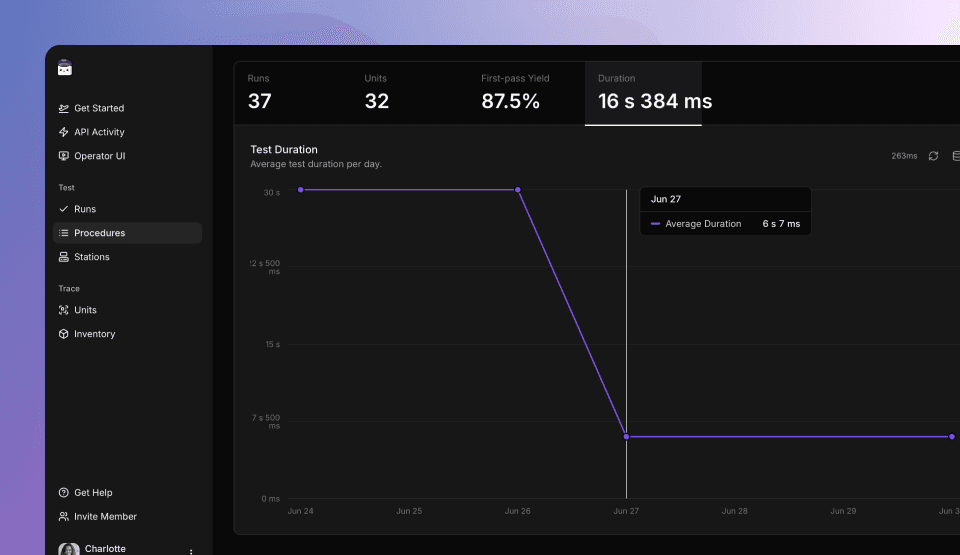

View test performance metrics and trends in the Run Analytics tab. Track daily patterns, failure rates, and timing data across all your test executions.

Runs

Daily test volume grouped by pass/fail outcomes. Identify failure spikes and testing trends over time.

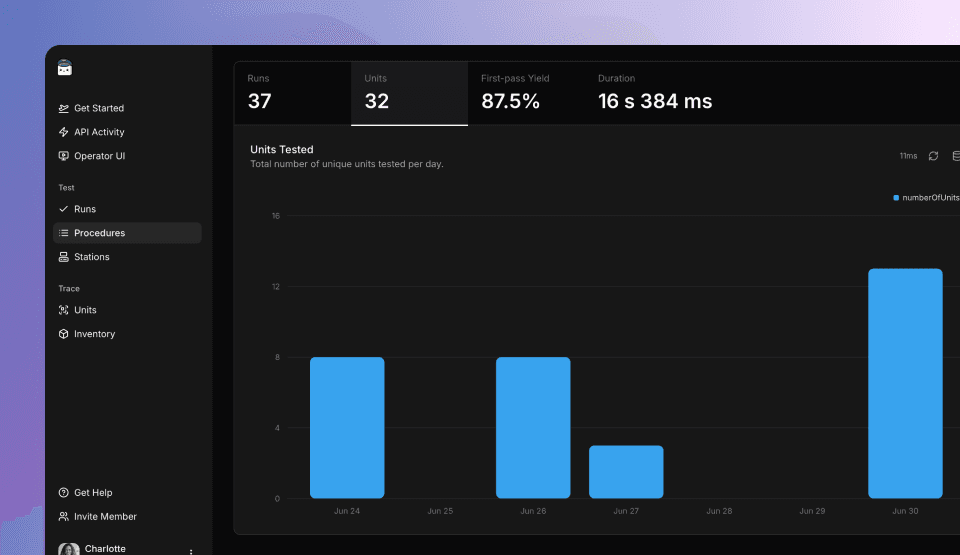

Units

Unique units tested daily based on serial numbers. Runs typically exceed units when devices are retested.

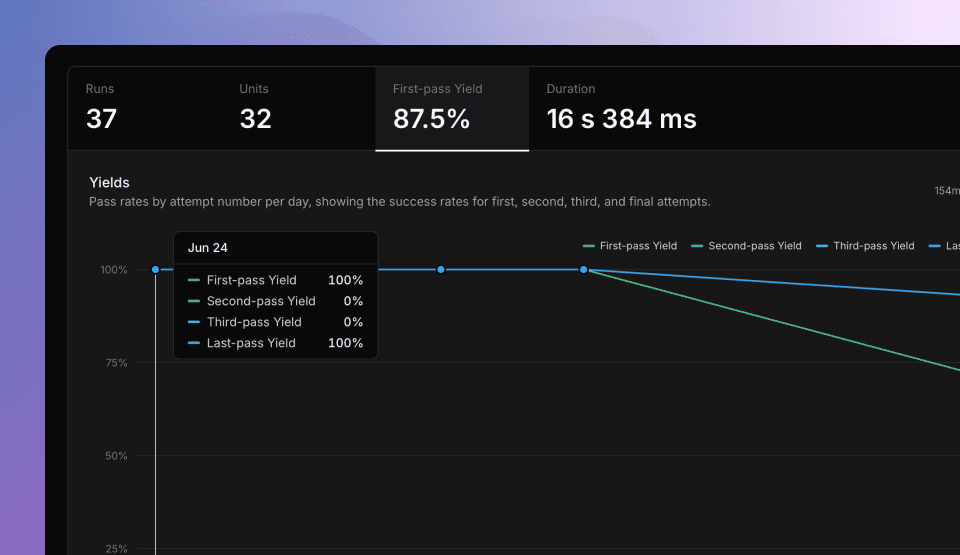

Yields

Pass rates by attempt number, grouped daily to track performance trends:

- First-Pass Yield (FPY): Percentage passing on first attempt

- Second-Pass Yield (SPY): Percentage passing on second attempt

- Third-Pass Yield (TPY): Percentage passing on third attempt

- Last-Pass Yield (LPY): Percentage eventually passing (useful for scrap rate estimation)

FPY is also known as throughput yield (TPY) in some manufacturing contexts.

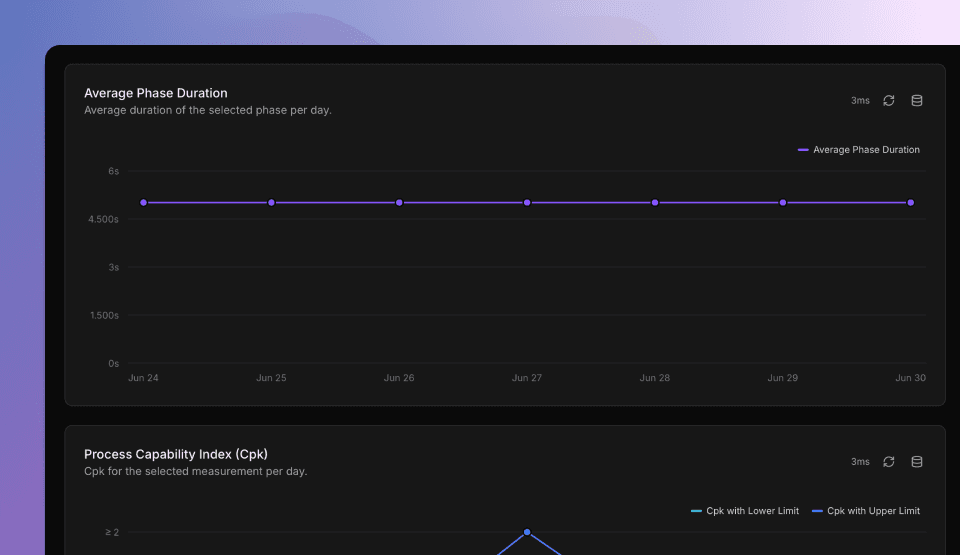

Run Durations

Average test duration per day. Detect performance regressions or timing changes in your test process. For individual phase timing, see Phases Insights.

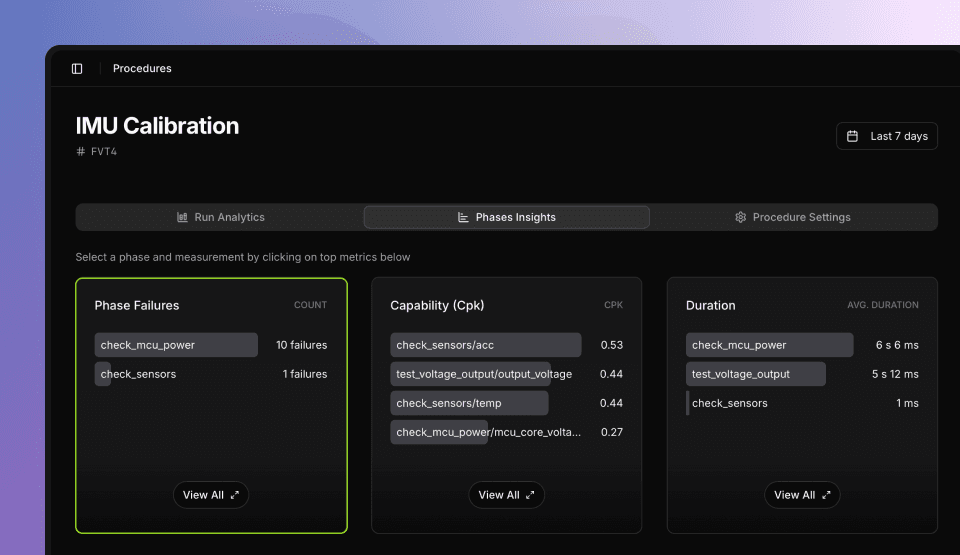

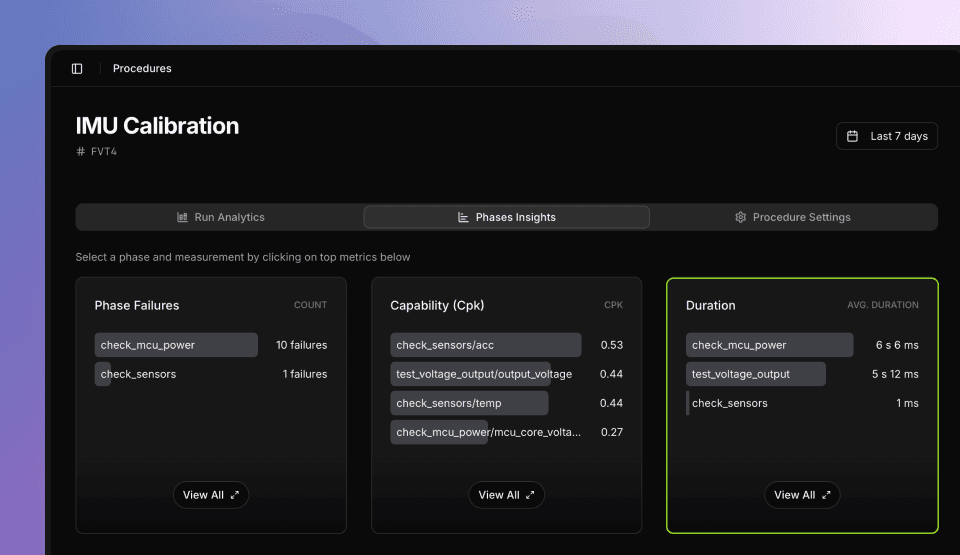

Get Phases Insights

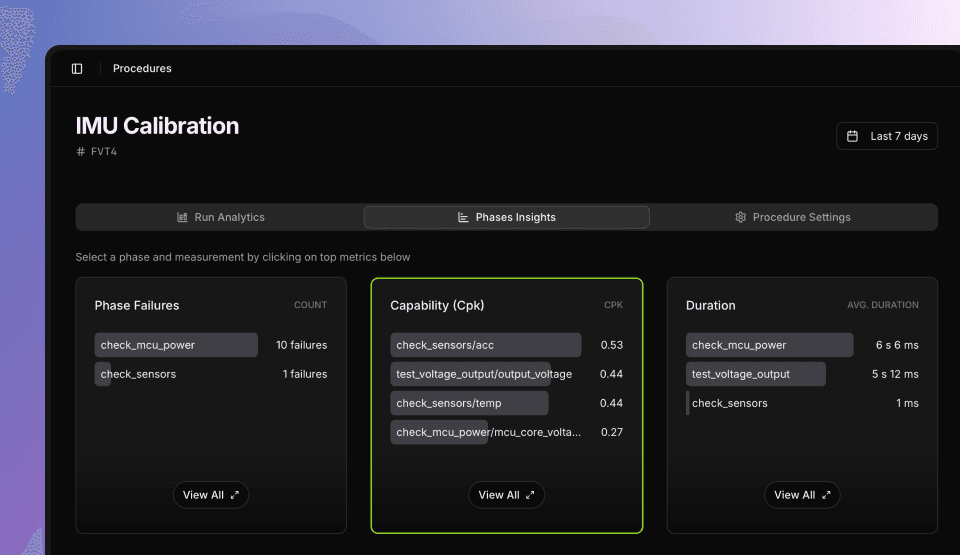

Analyze test issues at the Phase level: connection errors, unstable measurements, and timing problems. TofuPilot tracks each Phase individually to pinpoint issues and improve Procedures. Monitor performance over time, identify bottlenecks, and detect instability using Process Capability Index (Cpk) and control charts.

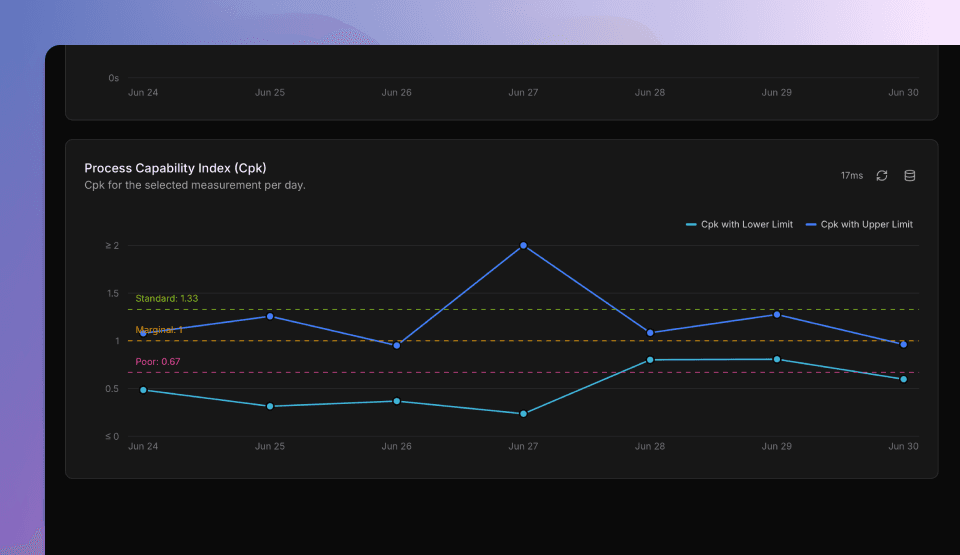

Process Capability Index (Cpk)

Cpk measures how consistently a test measurement stays within its limits. Applies to numeric measurements with at least one limit (lower or upper). TofuPilot calculates Cpk in real time for every numeric measurement of every Phase.

Use the Capability table to sort all Phases from highest to lowest Cpk. Select a specific measurement to see its daily Cpk evolution, calculated separately for lower and upper limits.

Formula and Interpretation

Cpk = min[(upper_limit - μ) / (3σ), (μ - lower_limit) / (3σ)]Where μ = Mean, σ = Standard deviation

- Cpk > 1.33: Process is well centered and stable

- Cpk ≈ 1.00: Process is marginal

- Cpk < 1.00: Process is not capable and improvements are needed

Low Cpk indicates your test is too variable or poorly centered. Can result from overly tight limits, measurement drift, or unstable instruments.

Improving Low Cpk

- Use the Capability table to identify weak Phases

- Check control charts for historical trends

- Apply filters by revision, batch number, or part to isolate root cause

- View Cpk variation over time for specific measurements (shown separately for lower and upper limits)

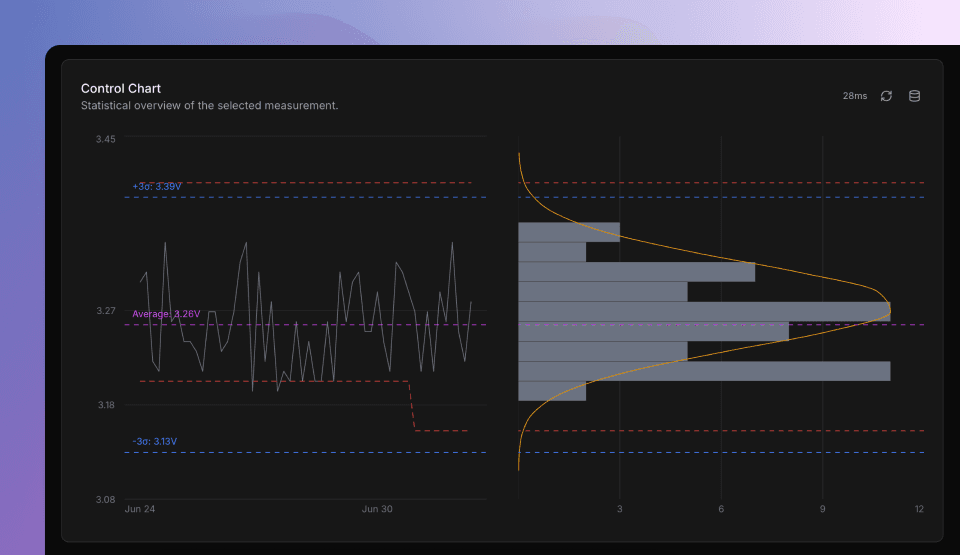

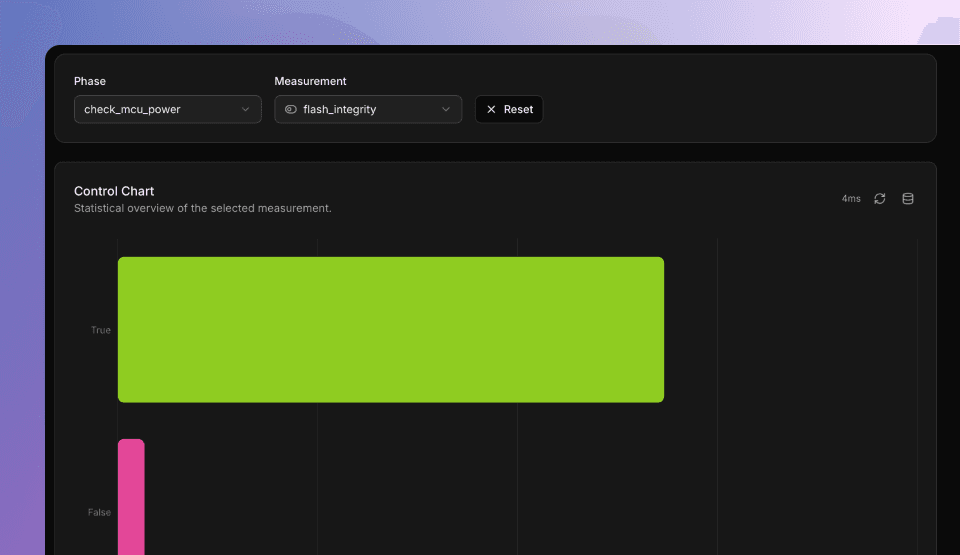

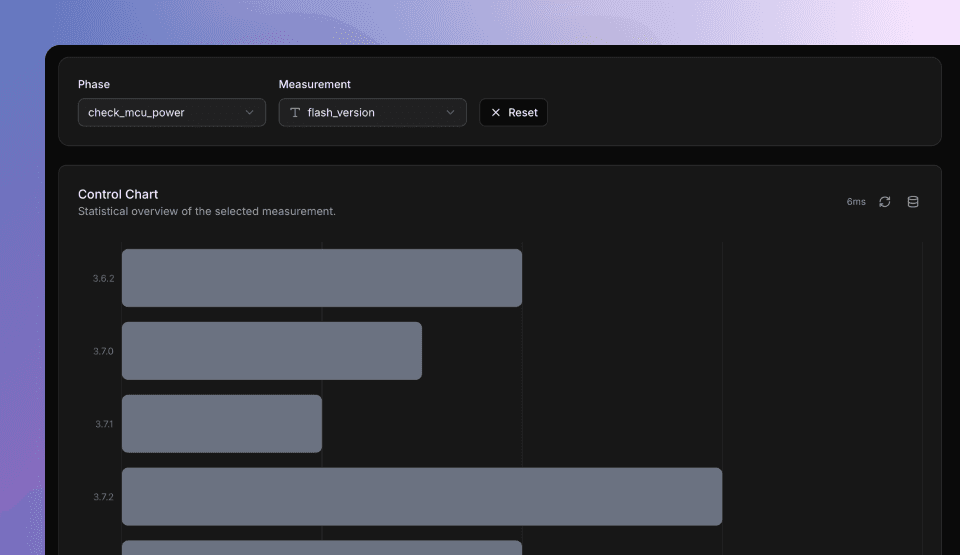

Control Charts

The Control Chart helps you monitor a selected phase’s measurement over time and detect drift, instability, or trends.

Control charts support numerical, boolean, and string measurement types.

Displays:

- All recorded values

- Lower and upper limits from your test script

- Average of recorded values in the selected date range

- ±6σ standard deviation

- A histogram with a Gaussian overlay

Measurement Types

Numerical: Values and limits pulled directly from your script. TofuPilot automatically computes average, standard deviation, and histogram based on selected data. If your script changes test limits over time, the chart reflects this with daily limit curve updates.

Boolean: Expected values displayed in green, unexpected values in pink.

String: Expected values displayed in green, unexpected values in pink. If no validators exist, all values displayed in gray.

Phase Failures

Identify which test Phases fail most often.

The Phases Failure table lists all failing Phases, sorted by failure count. Phases that never failed are not shown.

Phase Durations

The Duration table lists Phases by average duration (longest first). Identify bottlenecks in your Procedure.

Select a specific Phase to see how its average duration evolves day by day in a dedicated chart.

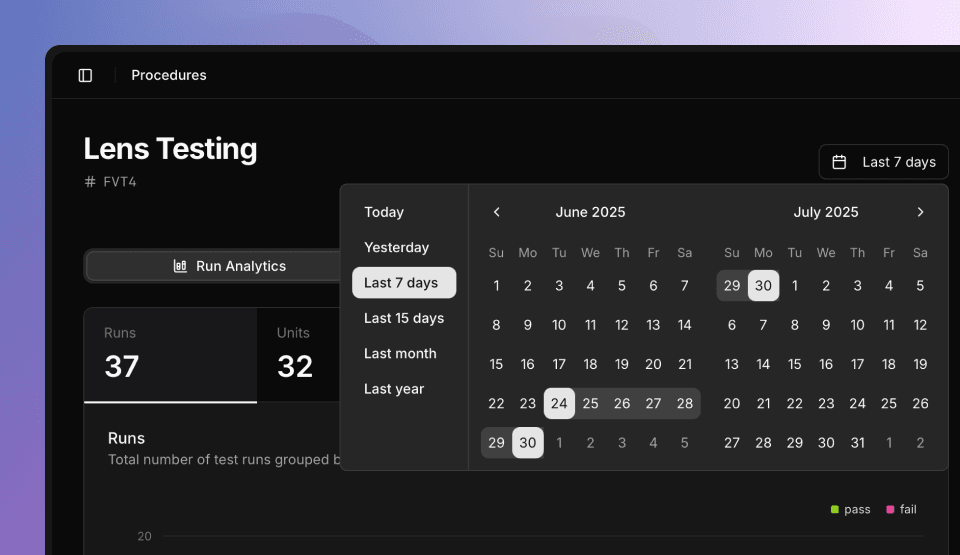

Filter analytics

Filter analytics across Run and Phase views to narrow down root causes. Filters apply to all charts and tables. Reset all filters by clicking Clear Filter.

Filter Types:

- Date: Select specific day or date range (default: last 7 days)

- Metadata: Source (user/station), batch, Procedure version, part name/revision

- Phase-specific: Select specific Phase and measurement from tables or dropdown

Rename Procedures

Rename the Procedure or its procedure_id directly in the app.

Go to the Procedure page, then click Procedure Settings. Edit its Name and ID.

How is this guide?